- Home

- Glass Fabrication Service

- Glass Strengthening & Thermal Glass Tempering

Hongxi offers glass chemical strengthening and thermal tempering solutions. Tempered glass features higher strength, thermal stability and safety performance than untreated glass. The impact strength of tempered glass is 3~5 times higher than that of common glass with the same thickness and the bending strength is 3~5 times higher. Tempered glass also has better thermal stability and the temperature change range it can withstand is 3 times wider than that of common glass, which is about 200℃. When broken by external forces, the tempered glass will shatter into honeycombed particles with obtuse angle, which won't hurt human body. Tempered glass is widely used in furniture, electronics, ornament, lighting industry and more.

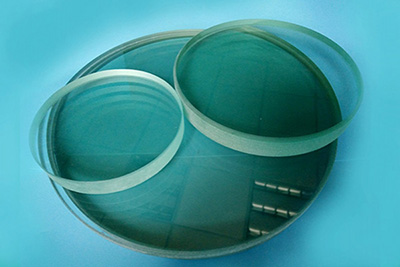

The chemical strengthening equipment can form a protective film on glass surface through the ion exchange of sodium hydroxide, which can significantly improve surface hardness of glass.

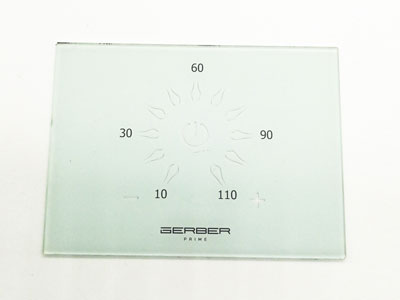

Chemical strengthening technique is appropriate for handling small-size glass with thickness<1mm and diameter<45mm. Therefore, chemical strengthening is widely used in optical glass industry which requires high precision.

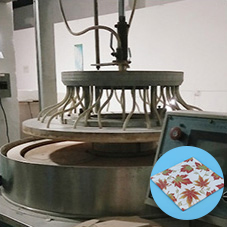

Heat tempering process can change stress on glass surface by high temperature, enhance glass hardness and prevent glass from shattering into dangerous shards and hurting people when broken.

We have thermal tempering furnace and hot bending furnace, which enable us to produce flat tempered glass and curved tempered glass. Hot bending process is usually used for bending large-size glass of radius over 1500mm and it can deliver reliable safety performance. Our bent tempered glass is often utilized as lampshade.

According to customer's requirements, full- or semi-tempering processing is selectable. Hardness of the tempered glass will be inspected through falling ball test.