- Home

- Glass Fabrication Service

- Glass CNC Machining

By usage of the most advanced glass machining equipment, Hongxi is capable of handling glass of various sizes and materials even including the toughest materials like quartz and high pressure gauge glass.

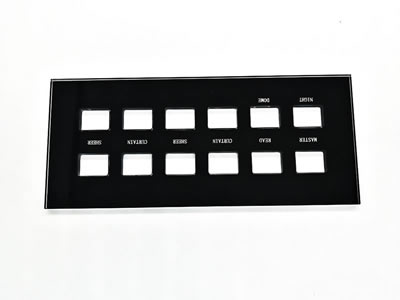

Our CNC engraving and mining machines can perform drilling and inner hole deburring. They are good at handling tiny and precise workpieces with size down to 5mm. When a hole is drilled, a burr is usually generated. CNC engraving machinery can be used as a deburring tool. In addition to CNC engraving equipment, we also have waterjet and laser machining systems to handle glass parts that require high accuracy or feature low thickness. The selection of machinery is decided by your actual material requirements.

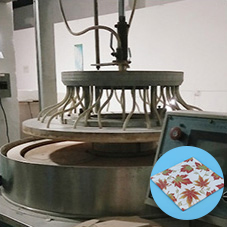

Glass straight line double edging machine adopts dual linear guide rails, it is capable of grinding, edging and polishing two straight-line edges of glass in one pass. The transmission is conducted by means of two ball bearing guide screws, which ensure a stable working speed with zero-clearance movement while reducing frictional resistance and guaranteeing high repeatability. It can be configured with other glass processing equipment such as glass loading /unloading table and glass cleaning machine to form a complete glass manufacturing line.

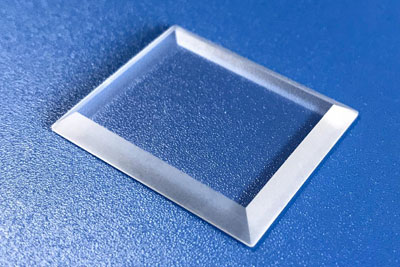

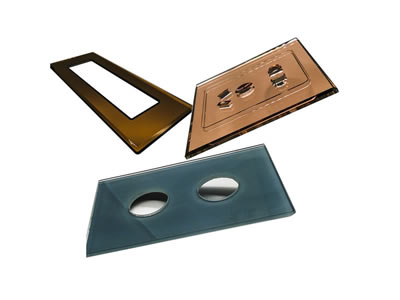

Hongxi has professional glass shape edging and beveling machines suitable for processing peripheral edges of medium or small size glasses. By changing the molds and grinding wheels, various complicated glass shapes can be formed with uniform sizes and bevels. We are capable of processing different glass edges to meet your various applications, such as sight glass, flashlight lens, step light glass, dive mask lens, glass cookware lid, mirror glass, and other glass products.